THE JOURNAL

Many hands make light work, as the saying goes, and it bears true at R.M.Williams. More than 80 pairs of hands contribute to crafting the Australian brand’s iconic Craftsman boot in a signature process that is as precise and painstaking as the finished boots are easy and enduring.

It is a process of studied craftsmanship that remains faithful to the vision of its founder, Mr Reginald Murray Williams, a business-minded bushman who got his start in the footwear trade almost 90 years ago in his beloved hometown of Adelaide, South Australia. Williams’ origin story is the stuff of folk legend: he originally learnt leatherworking skills from a passing horseman and then began making leather goods in his father’s shed in 1932. The location, 5 Percy Street, remains an R.M.Williams store today.

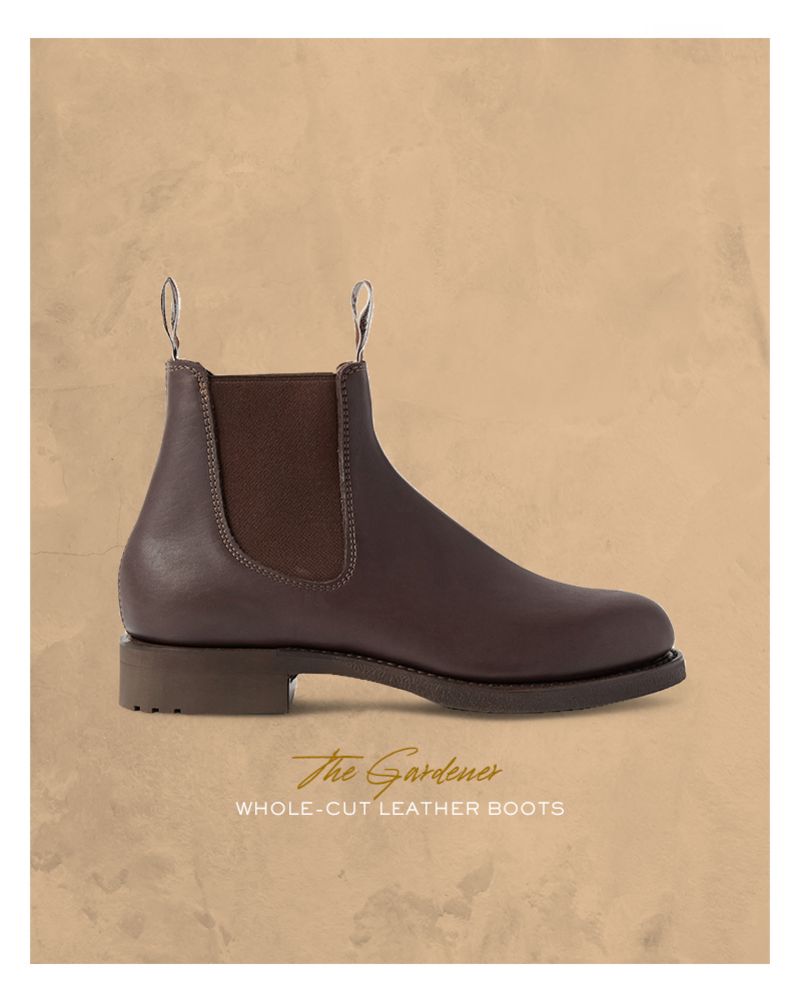

Other foundations remain; originally built for the men and women of the tough and unforgiving Australian outback, R.M.Williams footwear was grounded in a code of craftsmanship that is an integral part of every stage of production today.

“Inspired by and designed for the rugged conditions of the outback, R.M.Williams footwear has always been about endurance”

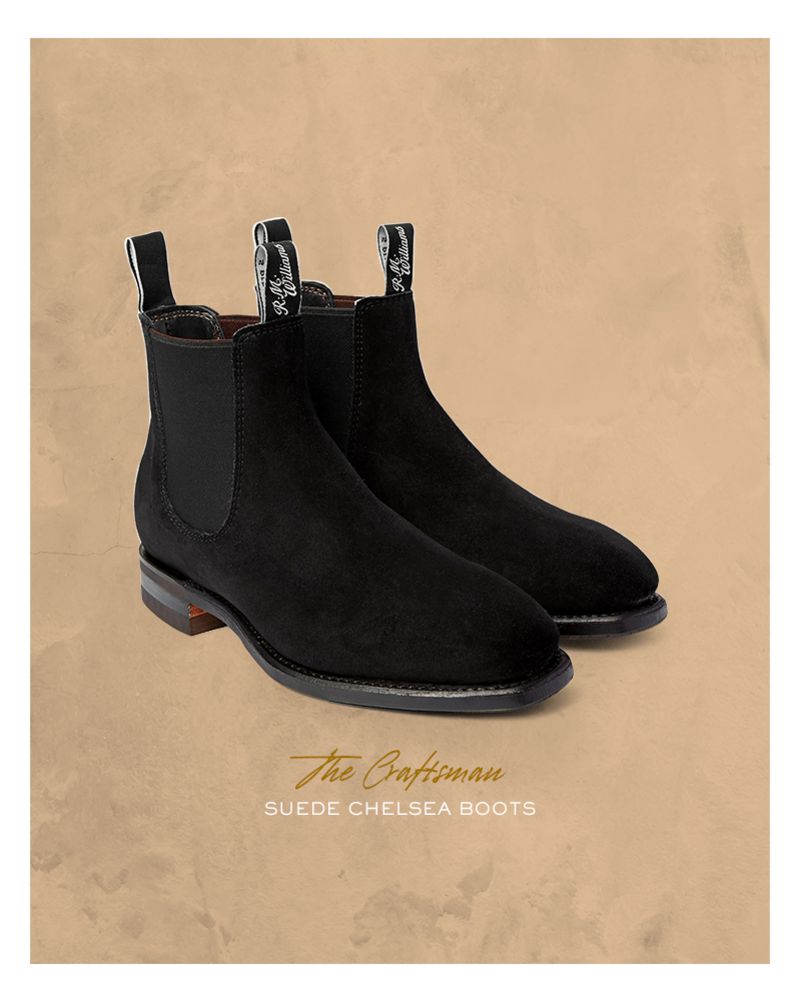

To document the work of all 80 or so craftspeople would necessitate a full-length movie, but there are certain points at which their artisanal skills are most evident. The process begins with a single piece of premium quality leather. In a highly skilled process that a machine has yet to surpass, the first of 80 pairs of hands assesses the hide for quality, natural character and light.

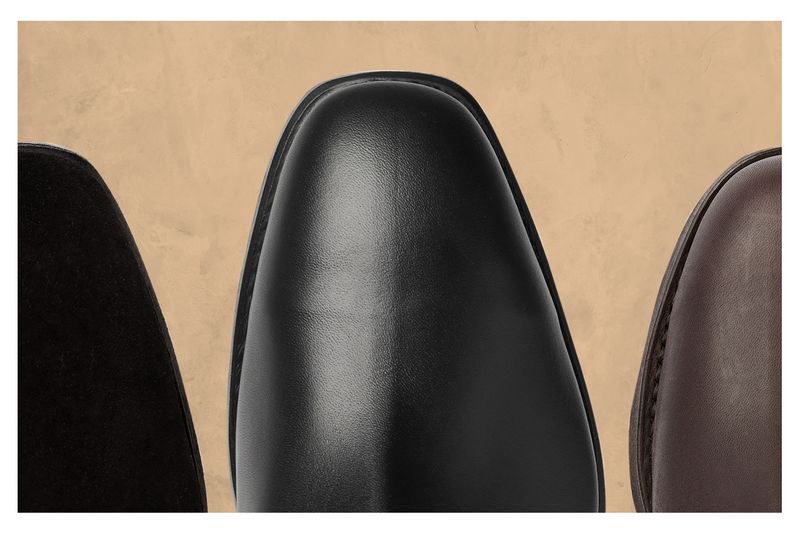

Machines do lend a helping hand along the way; in a process called clicking, craftspeople cut out the unique shape using sharp steel-blade and precision. It’s here that the distinctive R.M.Williams silhouette, an icon of Australian design, begins to emerge.

Inspired by and designed for the rugged conditions of the outback, R.M.Williams footwear has always been about endurance. The curved boot shape is created by putting stress on the leather, so premium materials are essential ensure natural character and strength are maintained.

The lasting process is where the boot really takes shape. The leather upper is pulled over a foot-shaped mould called a last: the lasters work by feel to mould the leather into shape and ensure the correct tension for size and fit.

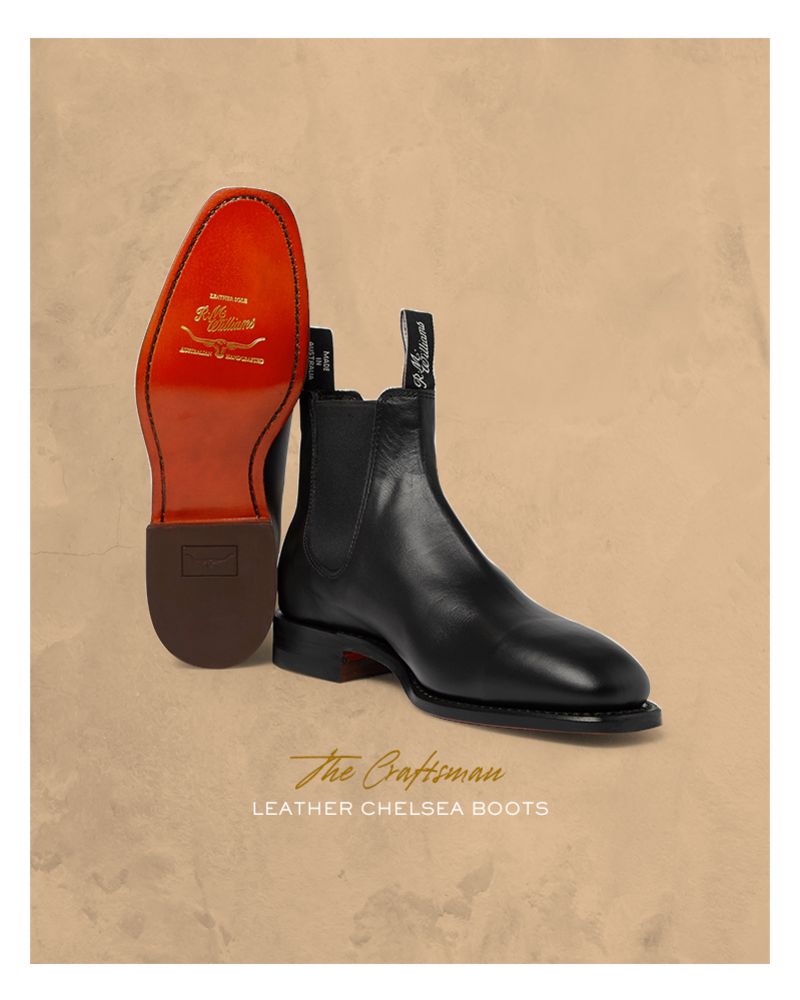

At R.M.Williams, each craftsperson has a specific role. The handful who are trained in traditional construction methods stitch the soles. After the leather is sanded, signature red gum stain, resonant of the iron-rich soils of the Australian landscape, is applied by hand. Then the fine brass plaque bearing the personal signature of the Master Craftsman, the brand’s most senior bootmaker, is added to the Signature Craftsman boot. Finally, with a leather heel sock fixed inside, the boot is carefully cleaned, buffed, polished and finished, at which point it’s ready for one final pair of hands: yours.