THE JOURNAL

A Santoku kitchen knife. All photographs courtesy of Mr Chris Terry

The award-winning food writer shares his ideas for the perfect culinary utensil.

**To celebrate the release of his latest book, _Knife _– an exhaustive love letter to the essential kitchen companion – we asked the writer, broadcaster, restaurateur and “unrepentant food geek” Mr Tim Hayward to craft us his dream knife. **

While researching Knife, it’s obviously been on my mind throughout to design the ideal knife. In truth, some of the specialist blades like yanagibas and flexible filleters are already perfectly evolved and would always have a place in my roll, but the general, day-to-day, chef knife could be tweaked and improved – particularly if money were no object. One of the world’s best knife-makers is the American Mr Bob Kramer, who is currently making a tiny number of cripplingly expensive custom knives out of metal recovered from a meteorite. I think I’d take a chunk of that as my starting point.

I’d take my lump of meteorite down to Blenheim Forge in Peckham, London, where they are hand-forging blades by methods they’ve evolved from ancient Japanese techniques for making Samurai swords. They could handle the process of beating out and folding the metal again and again to create the gorgeous “damascus” pattern. During this long process, blades are sometimes “wrapped” around a core of another steel which takes a better edge. Blade geeks love a bit of mystery and exclusivity here, so I’d need to find a secret alloy currently being researched by Nasa for use in surgical lasers and called something like “Unobtanium 479/K”.

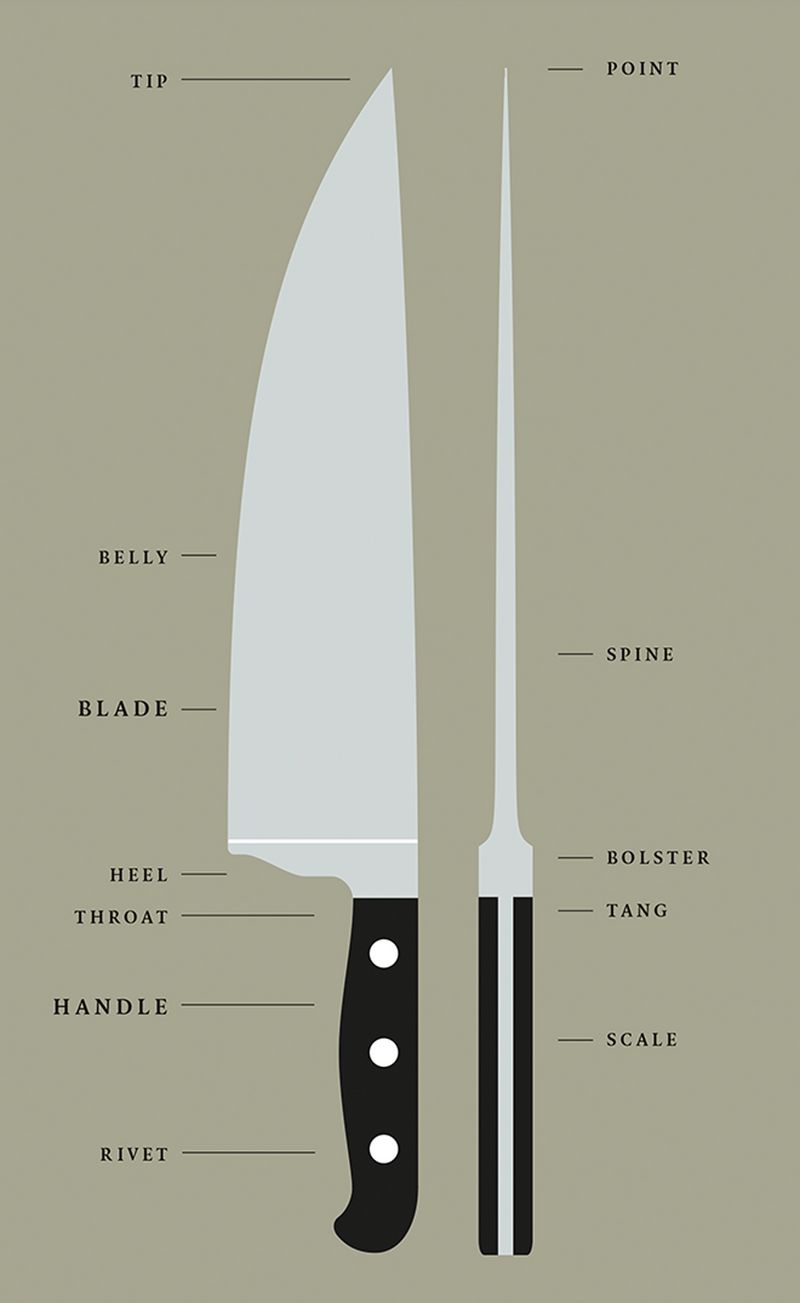

The anatomy of a knife

There’s a great general-purpose Japanese knife called Santoku, which has a thin, light blade that’s a little like the Western chef knife in profile but with a straighter cutting edge. Santoku means “three virtues”, apt for the knife because it serves the same functions as vegetable, fish and meat-slicing knives. I’d go for a Santoku-inspired shape with a slightly deeper “throat” (top of the handle) to accommodate my big hands, and I’d have most of the point removed. There’s remarkably little use for the tip of a large blade in the kitchen, and it remains part of current design largely through tradition. I’d have the blade shaped by Ben at Blok Knives in Derby, England. He’s a master at the belt sander and has his blades hardened by the same people who do Formula 1 engine parts and bits for nuclear reactors. I’d brief him to take the blade down as thin and light as he could while balancing the stiffness.

I could send the shaped blade to Sakai in Japan to have the edge put on. There are specialists there who can sharpen the blade to different degrees along the edge to suit your cutting style, but in truth, my skills wouldn’t deserve that. I’d nick bones or the chopping board so often that I’d constantly be sending it back. There’s a young chap – lets called him “J” – who is currently the best “edge man” in the UK, but I can’t tell you where to find him, he’s too precious. You’ll need to do your own research among the secretive community of knife-makers. I could go back to “J” once a month.

Mr Tim Hayward’s knife rack at home

Most collectors choose arcane organic handle materials, such as rare woods or bone, but I’d go with high-performance thermoplastics developed for military use, such as G-10 or Kydex – discrete and functional. I prefer a traditional full-tang handle (a heavier handle where the blade extends throughout) to the “Yo” type fitted to Japanese knives, but because the tang adds weight, I’d have it “skeletonised” – lots of lightening holes drilled in it, concealed inside the handle. Knife makers don’t like doing this because the tough steel chews up machine tools, but you can, if you’re smart, get it done before the blade is hardened.

Finally, I would emphatically not have my name engraved on it. A knife this good has a character and many parents, so any single name on it would be wrong – and, of course it wouldn’t need identifying as it would never leave my side.

Knife: The Cult, Craft And Culture Of The Cook’s Knife (Quadrille) is out now